Alnico Magnets, Industrial permanent Magnets

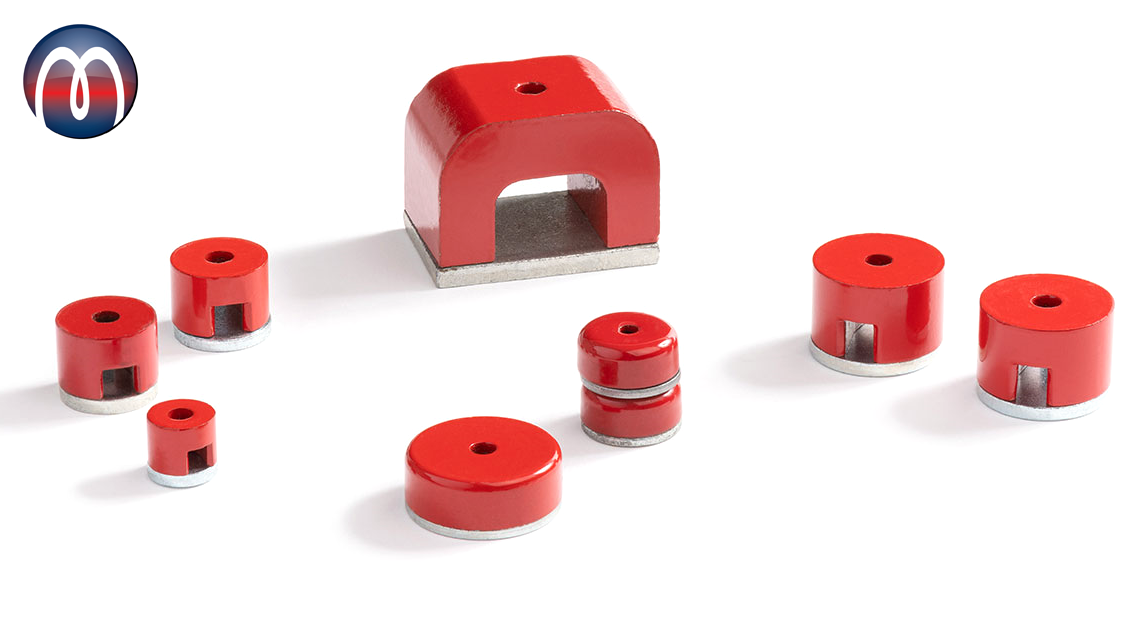

Alnico (Aluminium, Nickel and Cobalt) magnets are permanent magnets available in sintered or cast Alnico and in different shapes, including cylinders, blocks and segments. Magnets composed of an alloy of Aluminium, Nickel and Cobalt, as well as Iron and other traces of metallic elements. Excellent resistance to high temperatures (up to 500°C) and corrosion, extreme mechanical solidity, possible horseshoe shapes, round button magnets, cylinders, blocks, segments. Buy now! |

Alnico Magnets

Alnico Magnets

Alnico is an alloy produced by mixing aluminum, nickel and cobalt with certain addition of other metals like copper, iron and titanium. Capable of producing strong magnetic field, it has an excellent linear temperature characteristics and has wide industrial applications.

As one of the members of magnets family, Alnico remains the workhorse of the permanent magnet industry and can be relied upon to deliver impressive flux density at an economical price. Alnico also boasts the lowest temperature coefficient of any commercial magnet material (0.02% per degree centigrade) allowing for excellent stability over a wide temperature range.

The most efficient use of Alnico requires that it be magnetized after the magnet has been assembled with its pole pieces into the final magnetic circuit. Magnetic saturation at the end-use location requires the application of a magnetizing force 4 to 5 times greater than the coercive force of the material. For Alnico 5, a magnetizing force of 3000 oersteds (240 KA/m) is recommended. For Alnico 8, the magnetizing force should be at least 7000 oersteds (560 KA/m). The magnetizing force need be applied only momentarily. Thus, impulse magnetizers employing a capacitor discharge are commonly used. Direct current magnetizers are also effective.

Wholesale prices: Click here to request quote

Alnico

Alnico

As one of the members of magnets family, Alnico remains the workhorse of the permanent magnet industry and can be relied upon to deliver impressive flux density at an economical price. Excellent temperature stability, high residual induction, and relatively high energies characterize Alnico materials, composed primarily of alloy of Aluminum, Nickel, and Cobalt. They are manufactured through either a casting or sintering process. Cast magnets may be manufactured in complex shaped, such as horseshoe.

More About Alnico Magnets

More About Alnico Magnets

Alnico magnets are composed of aluminum, nickel and cobalt. They offer a very strong magnetic field, second only to rare earth magnets, and are commonly available in horseshoe, cylinder, or rod shapes.

The benefits of this unique material include:

- Flexibility in selecting the shape due to casting process

- Can be magnetized in one or all directions

- High energy

- Surface protection coating not required

- Temperature stability

Ideal for High Temperature Applications

Ideal for High Temperature Applications

Alnico is an extremely hard material that performs well in high temperature situations, offering a service limit of 550 degrees Celsius.

Types of Alnico Magnets

Types of Alnico Magnets

On the basis of manufacturing process and application alnico can be grouped into following types:

- Cast Alnico

- Sintered Alnico

- Bar Alnico

Alnico magnets can be fabricated into many shapes and types:

Alnico magnets can be fabricated into many shapes and types:

- Alnico horseshoe magnets

- AlNiCo rod magnets uncoated

Features

Features

- Alnico's are the strong magnets which can produce strong magnetic fields.

- Excellent resistance to corrosion

- They have superior thermal stability

- These magnets have some of the highest curie points of any magnetic material ranging around 800oC

- Some type of Alnico's are isotropic

- They have high magnetic flux density

Applications

Applications

Alnico magnets have applications in the following areas:

- Electric motors

- Electric guitar pickups

- Sensors

- Loudspeakers

- Cow magnets

- Automotive and electronic sensors

- Actuators

- Hall effect sensors

- Magnetron

- Reed switches

- TWT aomplifiers

- Communication

Manufacturing Process

Manufacturing Process

Casting or sintering process is applied for making alnico magnets. The first step involves the pouring of molten metal alloys into moulds. Later it is passed through various heat cycles. The resultant magnets have rough surface which after machining gives a glossy look. Sintered magnets are produced by compacting fine alnico powder in a press, and then sintering the compacted powder into a solid magnet. Alnico magnets can only be magnetized only in the field having magnetizing fields of about 3 kOe. Since these magnets have low coercivity they, must be protected from the adverse repelling fields as this could partially demagnetize the magnets.

Magnetizing

Magnetizing

After the tolerance magnetizing is effected. As alnico magnets are brittle, they must be protected from hard blows and handled with care. It should be magnetized in a proper magnetic field and must be prevented from the repelling fields as it is prone to demagnetization.

Wholesale prices: Click here to request quote

We ship our Magnets worldwid via Sea or Air Shipment

Who supplies high quality Alnico magnets?

Who supplies high quality Alnico magnets?

Magnosphere produces magnets at great prices, produced and delivered on time for all areas of industry, automotive, aerospace, electronics as well as in the design sector, trade fair construction, offices and for the home.

We are an ISO certified shop and carry the Trusted Shops seal. We have successfully completed more than 300,000 orders and offer our ever-growing customer base 24/7 customer service.

All items are available for immediate delivery in large numbers with daily dispatch. Our selection is your win! Thousands of satisfied customers! Buy from a company with the highest quality standards and customer service with flexible and diverse payment options and conditions.

We can also custom manufacture these to fit your exact specifications using our in-house global manufacturing facilities and team of experienced engineers. Need high quantities of magnets at the lowest and fairest price possible? Just let us know what you are looking for and contact our Customer Care Team by sending us a request for quote! We'll work with you to determine the most economical way of providing you with what you need.

Trust in our experience and convince yourself of our service and our products and we look forward to welcoming you to our magnet shop at Magnosphere. You are welcome to contact us by eMail: info(at)magnosphere.co.uk. Available 24/7 x 365 and we are also there for you on public holidays! Or just give us a call.

ROHS-Directive

![]() Magnosphere conforms to the RoHs directive and the Reach and PFOS regulations. Directive 2002/96 / EC of the European Parliament and of the Council, of January 27, 2003, on waste electrical and electronic equipment (WEEE).

Magnosphere conforms to the RoHs directive and the Reach and PFOS regulations. Directive 2002/96 / EC of the European Parliament and of the Council, of January 27, 2003, on waste electrical and electronic equipment (WEEE).

- Hotline:+49 (0) 2241 959450

- Telefax: +49.2241.9594520

- eMail: info@magnosphere.co.uk

We are very proud to offer excellent customer service. We know that without our clients, we would not be here. If you have any questions about your order or something else, please call or email us!: info(at)magnosphere.co.uk

24 / 7 x 365 Including holiday periods! Our customer service team is available to help you!